Now that The Torqeedo Shop has been selling and servicing Torqeedo outboards for few years we’re in a good position to suggest how best to care for your outboard and what servicing needs to be considered to keep it in tip top shape.

Regular Maintenance

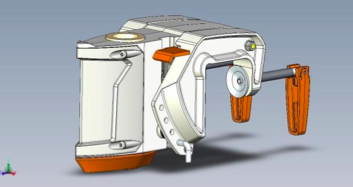

These outboards don’t require much to keep in good condition and there are some simple steps I recommend to keep them well protected in the harsh marine conditions we have here in Australia. I’m really impressed with the power of lanolin to keep all manner of marine equipment in good condition. The downside is that it can give a greasy feel to the equipment when the lanolin is fresh, and as it dries it becomes more like a waxy protection and better to the touch. When you first get your Torqeedo I suggest a generous spraying of lanolin especially on the transom bracket — this is a working mechanism and the lanolin serves as an excellent lubricant as well as a protecting from salt water. If you use you motor regularly it pays to regularly top up the protection with another spraying of lanolin every few months. For less frequent use it is enough to do a top up lanolin coat every six months.

Lanolin is a very good electrical insulator so it is important to cover the electrical connections when spraying with lanolin so that it does not get on the electrical contact surfaces. A good way to be sure of this is to connect the battery and control cables as you would for normal use and this will ensure the actual contacts are inside a waterproof seal and will not get any contact from lanolin. I like to spray a motor when it is in the warmth of the sun which keeps the lanolin liquid and allows it to penetrate as well as encouraging any excess to drop off. Have cloth handy to wipe down those surfaces that don’t really need any lanolin spray, such as the electrical cables and connection points. These are the parts that you will be handing and there is no point in getting lanolin on your hands when you use it. (but even if you do, we know that lanolin is good for the skin anyway).

I use both Lanotec and Lanox products and find them useful. I particularly like the Lanotec heavy duty lanolin. There are probably other products that will serve equally well.

For electrical contact protection and cleaning there are plenty of products available and my preference is a special purpose contact cleaner such as CRC Contact 2000 rather than a general purpose product such as WD40 and the like. Clean the electrical contacts every 1 to 2 months

If you use your motor in a salt water environment it is best to wash it down with fresh water after each use so there is not a salty layer on the motor. Be careful if your motor has been splashed or dunked in salt water that you wash down with fresh water especially in the vicinity of the electrical connections. Its preferable to never allowing the actual electrical contacts to be in contact with salt water. If the electrical connections are disconnected while wet with salt water its possible to contaminate the contact surfaces with the salty water. If this happens I recommend washing the open connection with fresh water to remove any salt, and to followup with contact spray. This will keep them in the best possible condition.

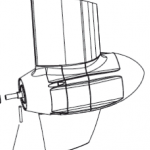

I like to remove the propeller regularly, to inspect for anything wrapped around the prop shaft, such as fishing lines or other small lines or cords. If wound tightly against the shaft it is possible to damage the shaft seal. Removing the prop also gives you the chance to check for damage to the drive pin. When putting the prop back on please cover the shaft and drive pin and washers with a generous coat of lanolin grease or other marine grease. To remove the propeller you’ll need a 17mm socket for the nyloc nut. If you do this regularly you will need to replace the nyloc nut (10mm) after every 3 or 4 removals. While the propeller is off connect the battery and throttle and run the motor slowly and take notice if the shaft is running true. If it is bent and/or running with a wobble please contact a service place for further advice.

Servicing

For Cruise models: Torqeedo recommends replacement of gear cap (including shaft seal), motor cap, and o-rings of the motor every two years or 300 hours of operation which ever comes first. This servicing is to be done by a Torqeedo approved service centre.

Other aspects such as electrical connections and mechanical operation, should be inspected at least annually and the drive pin should be replaced every year.

For Travel models: Torqeedo recommends that the shaft seal be replaced every 5 years. My additional recommendation is that the shaft seal be replaced every 300 hours if that occurs more frequently than at 5 year intervals.

For Ultralight and derivative models such as Hobie eVolve: Torqeedo recommends that the shaft seal be replaced every 5 years. My additional recommendation is that the shaft seal be replaced every 300 hours if that occurs more frequently than at 5 year intervals.